Instrumentation Hardware

Micro Steel Corporation Manufactures & Exports a wide range of designs in Instrumentation Hardwares as per international standards which has pneumatic and instrumentation applications in Chemical,Processing Plants,Oil,Gas,Petrochemicals,Pharmaceuticals and Power generation industries.

Syphon Tube

Manufactured and designed to protect instruments from higher temperature & direct contact of live medium with instruments. We produce pigtail steam Syphon Tubes in carbon steel, stainless steel & alloy steel with butt weld or threaded ports. Syphon Tubes can be obtained in standard and customized configurations from us.

| Material of Construction | Stainless Steel (SS304, SS316), CS, Monel, and Nickel Alloys. |

| Types | Q type, O Type, Plate U Type, Straight U Type |

| Range | Tube 1/2” To 3” (SCH 10, 40, 80 ,120) /Custom Size as required |

| Tube Length | 3 Meter, 6 Meter or as required |

| End Connection | SW, BW, Screwed, NPT, BSP, Male/ Female Threaded, Swivel type. |

| Pressure Rating | Up to 210 Kg / Cm² |

| Surface Finish | Polished Bright |

| Brand | MSC |

Air Header

Our company manufactures and design superior range of Air Headers, which is used for diverse sectors such as refinery, chemical, pharmaceuticals and fertilizer which has hydraulic and pneumatic applications. Our air headers are equipped with gauge savers, selector switches, melt bolts and condensing pots. Our range of air headers is available in different standard sizes and can be customized as per the industry specific requirement of clients.

Construction:

| Material of Construction | Stainless Steel (SS304, SS316), CS, Monel, Nickel Alloys and Brass |

| Manufacturing Type | Barstock, Forged or Tube. |

| Size Range | Tube 1/2” To 4” (SCH 10, 40, 80 ,120) /Custom Size as required. |

| End Connection | SW, BW, NPT, BSP, BSPT |

| Surface Finish | Polished Bright |

| Brand | MSC |

Testing:

Gauge Snubber

Gauge Snubbers are Manufactured and designed to protect pressure gauges and instruments from system pressure surges and shock. Pressure damping (snubbing) is accomplished through the use of a porous sintered SS 316 element. When snubber is installed up stream from a pressure instruments , the response rate of the instrument is reduced and generally varies with the initial pressure drop across the porous metal element, and allows the instrument to smoothly come to line ressure.

Gauge Snubbers has applications in various industries as LPG processing plant, PetroChemical plant, Refinery.They are available in various range and are built as per clients’ design in accordance with ASME standards.

| NO. | DESCRIPTION | MATERIAL |

|---|---|---|

| 1 | BODY | SS 316 |

| 2 | SPINDLE | SS 316 |

| 3 | GLAND | SS 316 |

| 4 | WASHER | SS 316 |

| 5 | PACKING | TEFLON |

| Material of Construction | Stainless Steel (SS304, SS316), CS, Monel, Nickel Alloys and Brass. |

| Size Range | 1/4"F x 1/4"M 1/2"F x 1/2"M 1/4"F x 1/8"M 1/2"F x 1/4"M 1/2"F x 3/8"M Custom Size as required |

| End Connection | SW, BW, NPT, BSP, BSPT |

| Gland Seal | Buna “N”, VITON, PTFE |

| Surface Finish | Polished Bright, CS zinc plated & dichromated |

| Brand | MSC |

Testing:

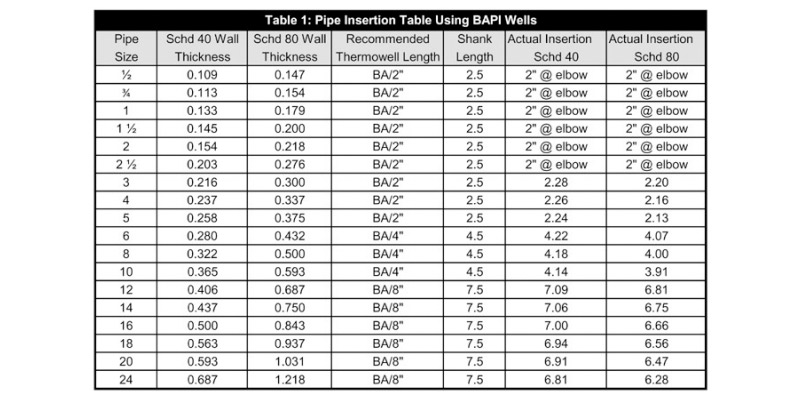

Thermowells

Thermowells are manufactured and designed confirming to ASTM/ASME PTC 19.3 and Wake frequency calculation is performed based on latest version 2016 to ensure the optimum suitable design of thermowell. Thermowells are cylindrical fittings used to protect temperature sensors installed in industrial processes. A thermowell consists of a tube closed at one end and mounted in the process stream.If the sensor fails, it can be easily replaced without draining the vessel or piping.

Gauge Snubbers has applications in various industries as LPG processing plant, PetroChemical plant, Refinery.They are available in various range and are built as per clients’ design in accordance with ASME standards.

| Material of Construction | Stainless Steel (SS304, SS316, SS310, SS321 ), CS, Monel, Nickel Alloys, Titanium and Brass. |

| Types | Bar Stock Threaded, Bar Stock Flanged, Bar Stock weld-in Type, Fabricated Threaded, Fabricated Flanged, Fabricated weld-in, Sleeved / Lined (alloy material / PTFE / others) Solid Sintered Tungsten carbide thermowells, Silicon Carbide Protecting Thermowell, Vanstone Type (shell design) Thermowell. |

| Manufacturing Type | Barstock, Forged or Tube |

| Size Range | Tube 1/2” To 10” /Custom Size as required. Offered with threaded and flanged process connections with BLRF, SORF, RTJ, flanges ranging from line size ½” and above and flange rating 150# to 2500# as per ASTM, ASME, API, JIS, BS standards |

| Shank Design | Straight, Tapered (Vertical), Stepped |

| Sheath ID | 5mm To 10mm Or above as required |

| Sheath OD | 12mm To 35mm Or above as required |

| Sheath Length | 2.5” To 7.5” Or Customize as required |

| Process Connections | Threaded, Flanged, Welded, SW, BW, NPT, BSP, BSPT |

| Testing | Chemical Analysis, Dimensional, Hydro Test, Dye Penetration, Bore concentricity, Physical, Microstructure, Post Weld H/T, NACE Compliance, Radiography, Ultrasonic, IGC various practices, IBR, PMI, etc. Approved WPS / PQR for various raw materials and welder and NDE qualification available . Regular Inspection and testing by BV, DNV, TUV, Lloyds, ABS, Moody, EIL, CEIL. |

| Certificates | Certificate of conformance, Test certificate, Material test certificates, 3.1 MTC, 3.2 MTC, Hydrotest reports, in-house special testing and third party testing certifications, as applicable are provided |

| Surface Finish | Polished Bright, Mirror Finish |

| Brand | MSC |

Bellows

Bellows are manufactured and designed in compliance with International Standards ASTM/ASME. Metallic Bellows are the expansion controls in pipelines, ducting & vessels which carry hot or cold fluids. Metallic bellows offer controlling the forces as well as stresses related to increasing as well as decreasing dimensional changes because of thermal contraction or expansion in the structures which involve ducts, vessels, piping and other end forms which are then transmitted to anchors and connected equipment.

We offer these Bellows in varied ranges and specifications in order to meet vast necessities of our valuable clients.

Bellows has Pneumatic & Hydraulic applications as in Diesel Engine Sets, Pipelines, Turbines, Compressors, Blowers, Vacuum Pumps ,Heat Exchangers and more in various industries.

| Material of Construction | Stainless Steel (SS304, SS316, SS310, SS321 ), CS, Monel, Nickel Alloys, Titanium and Brass |

| Types | Stainless Steel Bellow, Rectangular Bellow, Axial Bellow, Exhaust Bellow, Gimbal Bellow, Hinged Bellow, Manifold Bellow, Pressure Balanced Bellow, Metallic Bellow, Universal Bellow, Metal Expansion Joints With Fixed Flange, Metal Expansion Joints With Floating Flange |

| Size Range | 1” To 80” /Custom Size as required |

| Length | 100mm To 300mm /Cutom Size as required |

| Connector Type | Flange, Pipe |

| Shapes | Circular, Square, Rectangular |

| Pressure Rating | As per std, depends on the design & customisation |

| Surface Finish | Polished Bright, CS zinc plated & dichromated |

| Brand | MSC |

Bellow Hose & Corrugated Hose Pipes

Bellow Hose & Corrugated hoses are well-suited for the transport of liquids or gases under extreme circumstances. Micro Steel Corporation offers a wide range of stainless steel Hpse Bellow & Corrugated Hoses to meet the unique requirements of each specific application in terms of pressure, temperature, corrosion, movement, medium, vibration, length and type of connections. Hoses can be made of various materials such as galvanised steel, stainless steel AISI 304 or stainless steel AISI 316L for their corrosion resistance. Also available are the extremely corrosion-resistant corrugated hoses made from Monel, used for transporting chlorine and suitable for high pressure and temperatures up to 540°.

Hoses has their applications in various industries such as Electronic, Electrical, Pneumatic, Gas, Chemicals and Hydraulic.

Usage :

| Material of Construction | Stainless Steel (SS304, SS316, SS310, SS321 ), CS, Monel, Nickel Alloys, Titanium and Brass |

| Size Range | 1” To 12” /Custom Size as required |

| Hose Length: | Upto 12 Meters or as required |

| Connector Type | Flanged |

| Shapes | Cyndrical Pipe |

| Pressure Rating | As per std, depends on the design & customisation |

| Surface Finish | Polished Bright, CS zinc plated & dichromated |

| Brand | MSC |

| Material of Construction | Stainless Steel (SS304, SS316, SS310, SS321 ), CS, Monel, Nickel Alloys, Titanium and Brass |

| Types | Hydraulic Hose Pipe, Spray Hose Pipe, Vacuum Hose Pipe |

| Size Range | 1” To 12” /Custom Size as required |

| Hose Length: | Upto 12 Meters or as required |

| Connector Type | Flange, Swivel Nut ,NPT, BSP, BSPT, SW, BW |

| Shapes | Cyndrical Pipe |

| Pressure Rating | As per std, depends on the design & customisation |

| Surface Finish | Polished Bright, CS zinc plated & dichromated |

| Brand | MSC |